DH1S Danmuff

metal expansion joints

DH1S Danmuff

metal expansion joints

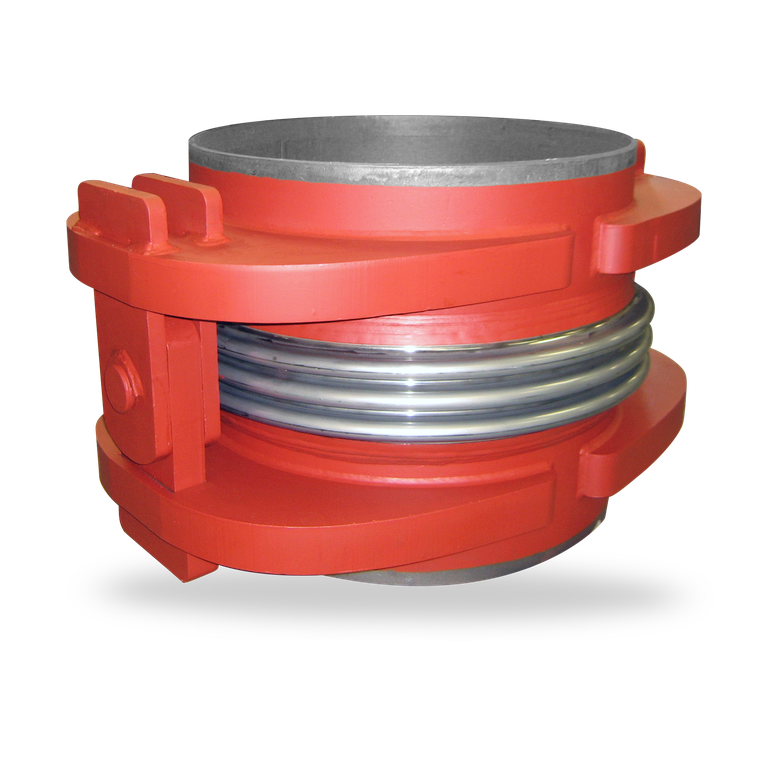

| Item | Description |

| 1 | Bellows |

| 2 | Outer casing / shroud |

| 3 | Internal liner |

| 4 | Cone section |

| 5 | Stop ring |

| 6 | Guide ring |

| 7 | Torsion protector |

| 8 | Media / line pipe |

DH1S Danmuff

metal expansion joints

Features

- Untied metal expansion joints mainly for district heating applications.

- External shroud with torsion protection, for district heating.

- Can be installed in series.

- Designed for large axial movements.

Advantages

- No significant pressure drop - reduced need for pumps and general power consumption for moving media, compared to pipe loops.

- Less space required around the joint - compared to pipe loops.

- Less supporting structure required – compared to pipe loops.

- Lower erosion rate (for abrasive media lines – compared to pipe loops with elbows).

- Multiply bellows with low spring rate and high cycle life.

Materials

- Bellows: 1.4541 (AISI 321)

- Connections: 1.0345 – (P235GH)

Other materials are available on request.

Standards and approvals

Design code:

EJMA, 1,000 Cycles

NDT and documentation:

Can be provided per customer request e.g.,

material certificates and NDT test reports.

EJMA, 1,000 Cycles

NDT and documentation:

Can be provided per customer request e.g.,

material certificates and NDT test reports.

Recommended applications

- Power plant technology

- Building services industry

- District heating & cooling

- Water cooling systems

- Air and steam transport lines

Notes

Custom designs and sizes are available on request. Untied metal expansion joints require guide and support.

DH type expansion joints are delivered 100 % preset (extended) using shear bolts, which are activated during startup / first cycle.

Similar products

AN Type expansion joints

- Tied custom metal expansion joints for general pressure applications.

- Designed for, and cover the mid temperature and pressure range for general process equipment.

- Mainly for angular movements.

- Tied metal expansion joints retain pressure thrust developed by internal pressure, through the use of hardware.

AX Type expansion joints

- Untied custom metal expansion joints for general pressure applications.

- Designed to cover the mid temperature and pressure range for general process equipment.

- Mainly intended for axial movements.

- Multiply bellows with low spring rate and high cycle life.

CB Clamshell metal expansion joints

- Bellows or expansion joints split into longitudinal segments for installation without opening pipework.

- Temporary repair solution for damaged expansion joints.

- Can handle axial, lateral and angular movements.

- The permissible combination and magnitude of movements depends on the application and the existing expansion joint that is to be repaired.