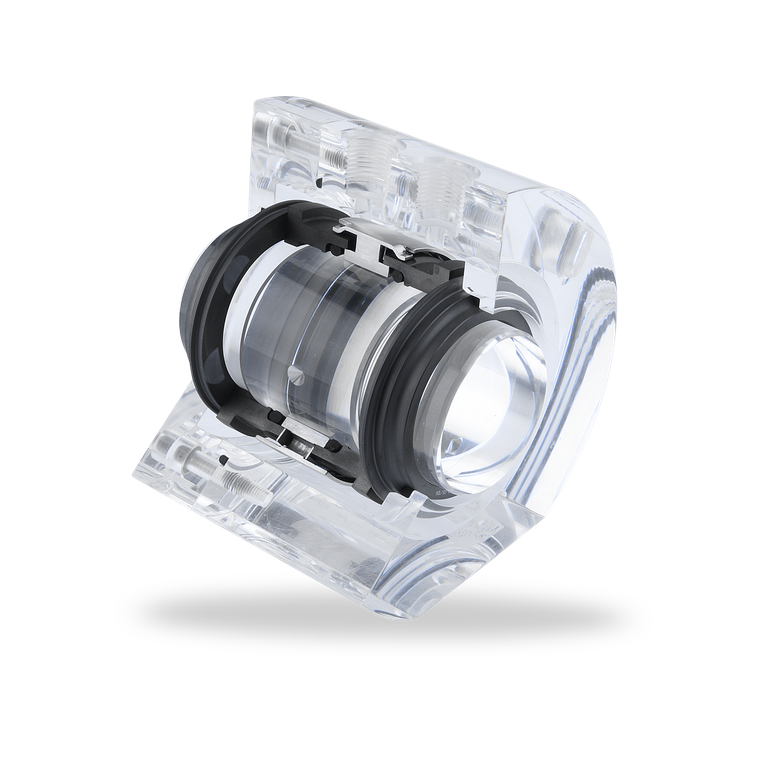

HRGS-D

HRGS-D

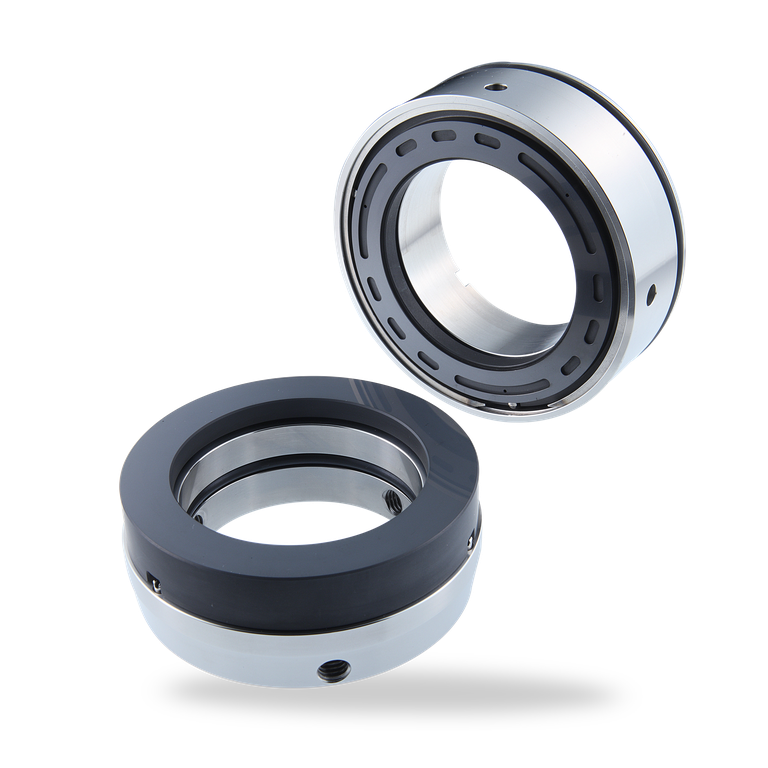

| Item | Part no. DIN 24250 |

Description |

| 1.1.1 | 472.1 | Seal face |

| 1.1.4 | 477 | Spring |

| 1.2 | 475.1 | Seat |

| 2.1.1 | 472.2 | Seal face |

| 2.1.4 | 485 | Drive collar |

| 2.1.5 | 477 | Spring |

| 2.2 | 475.2 | Seat |

| 3 | 523 | Shaft sleeve |

| 4 | 513 | Insert |

| 10 | 441 | Housing |

| 13 | Assembly fixture |

HRGS-D

Features

- Double seal

- Balanced

- Standard version with U-grooves (bi-directional)

- Gas-lubricated

Advantages

- Contact-free operation

- Suitable for solids containing media

- Internally pressurized

- Cartridge unit

- Does not open in the event of buffer pressure failure, self closing at pressure reversal

- HR principle with rotating seat

- No friction on the seal faces, no heat generated at the seal or in the medium

Materials

Product side (HRGS-DC, HRGS-DD):

Seal face: Silicon carbide (Q19, Q29)

Seat: Silicon carbide (Q1, Q2)

Atmosphere side HRGS-DC:

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

Seat: Silicon carbide (Q1, Q2)

Atmosphere side HRGS-DD:

Seal face: Silicon carbide (Q19, Q29)

Seat: Silicon carbide (Q1, Q2)

Springs: CrNiMo steel (G), Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Hastelloy® C-4 (M)

Seal face: Silicon carbide (Q19, Q29)

Seat: Silicon carbide (Q1, Q2)

Atmosphere side HRGS-DC:

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

Seat: Silicon carbide (Q1, Q2)

Atmosphere side HRGS-DD:

Seal face: Silicon carbide (Q19, Q29)

Seat: Silicon carbide (Q1, Q2)

Springs: CrNiMo steel (G), Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Hastelloy® C-4 (M)

Recommended applications

- Chemical industry

- Refining technology

- Gases and liquids

- Media which require high purity

- Environmental harmful media

- Pumps

Product variants

HRGS-DC

Gas-buffered double seal. The HRGS-DC is designed for applications involving fitting dimensions in line with DIN 24960 C or ANSI Big Bore standard, but can also be used even when the fitting dimensions are not of standardized nature if large, open spaces are available for installation. The CGSH is used as outboard seal up to nominal width 125.

Gas-buffered double seal. The HRGS-DC is designed for applications involving fitting dimensions in line with DIN 24960 C or ANSI Big Bore standard, but can also be used even when the fitting dimensions are not of standardized nature if large, open spaces are available for installation. The CGSH is used as outboard seal up to nominal width 125.

HRGS-DD

Acc. to API 682 configuration 3NC-FB, API Plan 74. The HRGS-DD corresponds to the HRGS-DC in terms of design principal and materials. It is designed for applications involving large shaft diameters of up to 200 mm (7.87") or fairly high pressure levels of up to 40 bar (580 PSI). The outboard seal used in such cases is the DGS.

Acc. to API 682 configuration 3NC-FB, API Plan 74. The HRGS-DD corresponds to the HRGS-DC in terms of design principal and materials. It is designed for applications involving large shaft diameters of up to 200 mm (7.87") or fairly high pressure levels of up to 40 bar (580 PSI). The outboard seal used in such cases is the DGS.

Similar products

CGSH-K

- For stepped shafts

- Balanced

- Rotating spring

- Single or double seal available

- Standard version with U-grooves, V-grooves optional (dependent of direction of rotation)

- Gas-lubricated

- Does not open in the event of buffer pressure failure, self closing at pressure reversal

EM300

- Balanced

- Independent of direction of rotation

- Stationary multiple springs

- API682 arrangement 2 containment seal

GSO-DN

- Seat rotating

- Stationary springs

- Double seal

- Balanced

- Standard version with V-grooves, U-grooves optional (independent of direction of rotation)

- Gas-lubricated